Planning your staircase

This week, I sat down with Anthony Simpson, Managing Director of local Christchurch staircase engineering company, Division Group. The team at Division specialise in staircase design mainly for new homes in Christchurch, Wanaka, Queenstown and The Marlborough Sounds.

Anthony and I chatted about all things “stairs,” and below I share his answers to some commonly asked questions about staircase design. If you’re planning some statement stairs in your home, Anthony’s answers might be helpful.

1. What are the normal dimensions for a stair tread?

2. What is the average thickness for a stair tread?

If it has a supporting tread underneath and a riser at the back, the treads can be as thin as 40mm. However, at the front, there must be a gap of a size that you cannot fall through, so it needs to be more than 100mm.

3. How many rises does the average staircase have?

4. What is the best wood to use for a timber staircase?

Usually the American white oak used would be lightly stained. If you start going to darker stains, it is better to use maple or ash hardwood as these hold the stain a lot better and are more stable under heat coming in through windows.

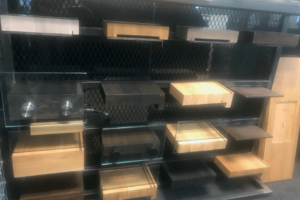

Stair designs

If you don’t have an architect, get in touch with Anthony and the Division Engineering team today as your first pick for stair manufacturers in Christchurch. Their designers, engineers & steel team will ensure your staircase ideas can become a reality.

About Division Group, Staircase specialists

Anthony moved over to New Zealand from the UK in 2005 where he established Division Group – a company still family-owned and operated ten years later. His company has since become renowned for being able to work in tight spaces, using specialist equipment to ensure your staircase can be installed even in tricky corners. This can make a difference especially for commercial stairs, as depending on the job, your tenants may not have to move out for weeks on end while the staircase is installed.

Anthony moved over to New Zealand from the UK in 2005 where he established Division Group – a company still family-owned and operated ten years later. His company has since become renowned for being able to work in tight spaces, using specialist equipment to ensure your staircase can be installed even in tricky corners. This can make a difference especially for commercial stairs, as depending on the job, your tenants may not have to move out for weeks on end while the staircase is installed.

Who is the best NZ staircase manufacturer?

Division Group, based in Kaiapoi, Christchurch, design and install a wide array of staircases to suit your structural needs and your aesthetic desires. These include exterior stairs, spiral staircases, curved stairs and curiously minimalist floating stairs. Anthony and his team work with a range of materials such as wood, glass and steel, offering combinations of different materials as well to create your unique staircase or realise the vision of your architect. They can help you with your new build or with a home renovation. Whatever your staircase idea, they can make it happen. It’s a bonus that they also do steel fabrication and architectural detailing, meaning you can get everything from steel framing, fireplace surrounds, and stairs to architectural letterboxes done by the same team.